Noise Control Solutions

Beechfield Design Consultancy Limited design, manufacture and supply:

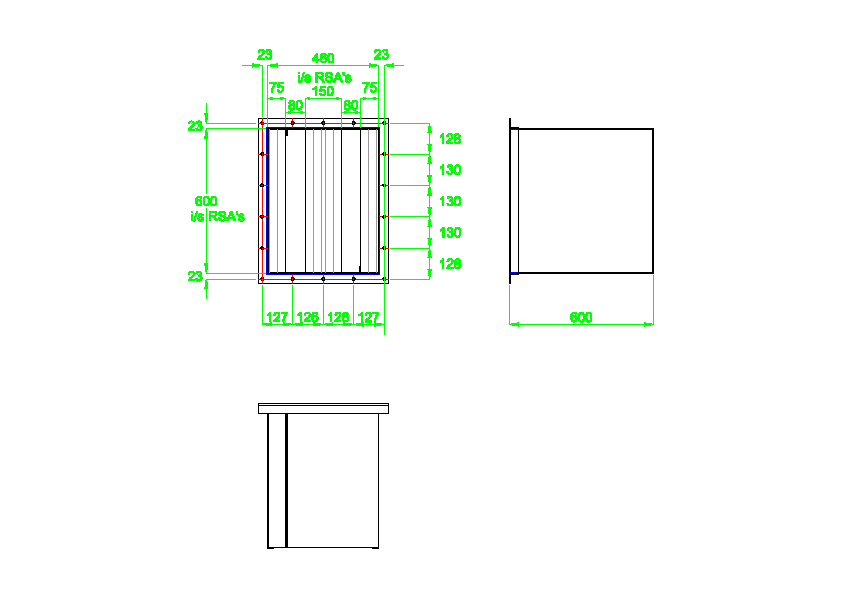

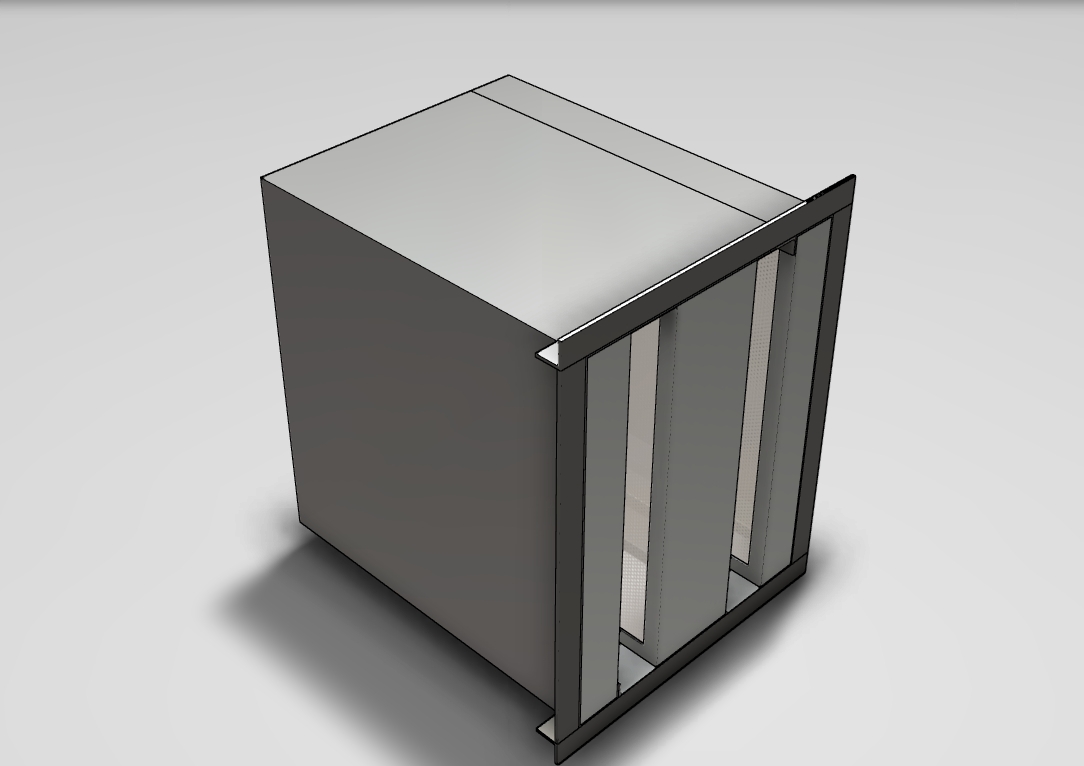

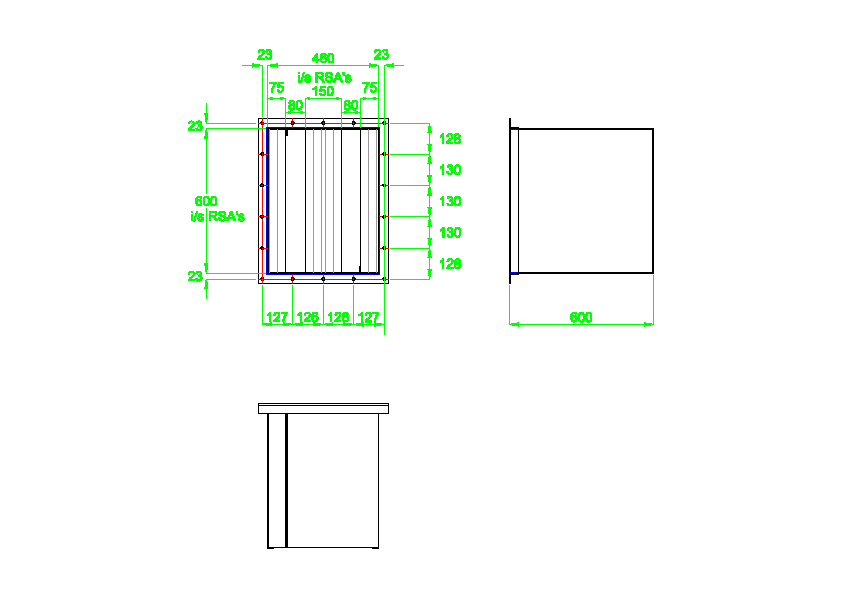

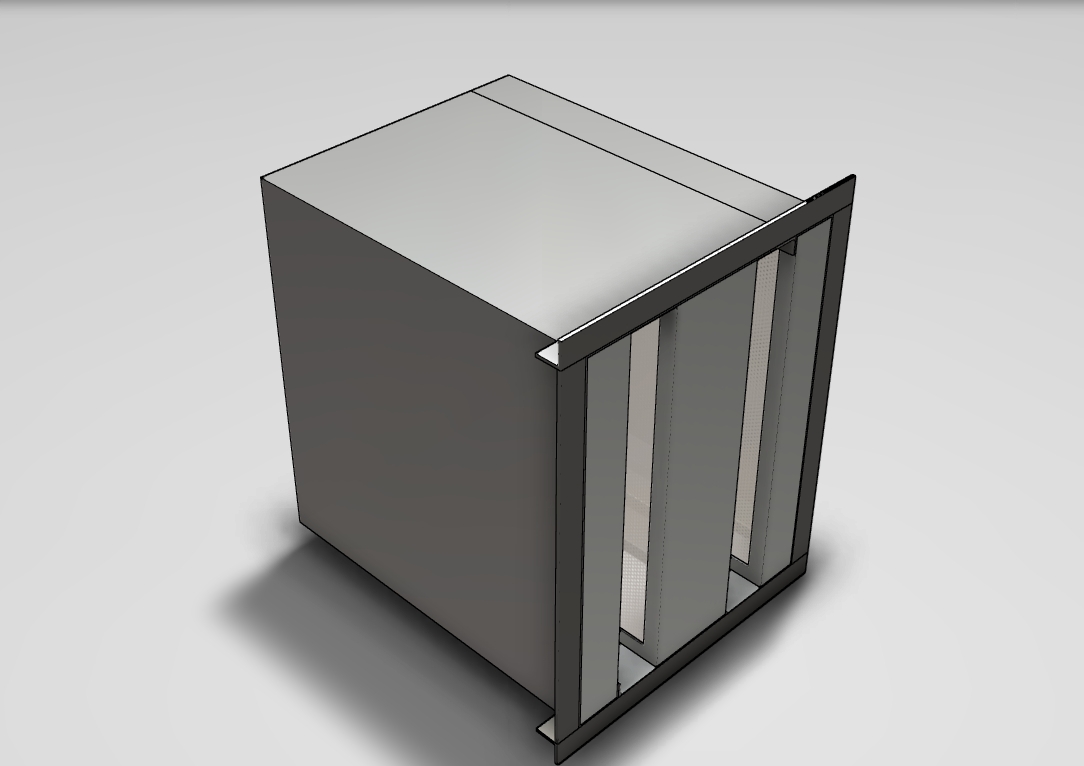

Rectangular Splitter Attenuators

- Available in various sizes and various widths

- Can be modular for heavy or awkward installations

- Made from a range of materials and specifications

- Standard constructionPre-galvanised steel outer body

- Perforated steel inner

- Acoustic infill with glass cloth wrapping

- Painted RSA flanges

- Optional construction

- Self formed flanges

- Hot dipped galvanised steel RSA flanges

- ‘Bull noses’ or airfoils for reduced pressure drop

- Mesh guards

- Stainless steel construction

- Powder coated steel outer construction

- Acoustic material can be wrapped in a polyester based film for moisture laden environments

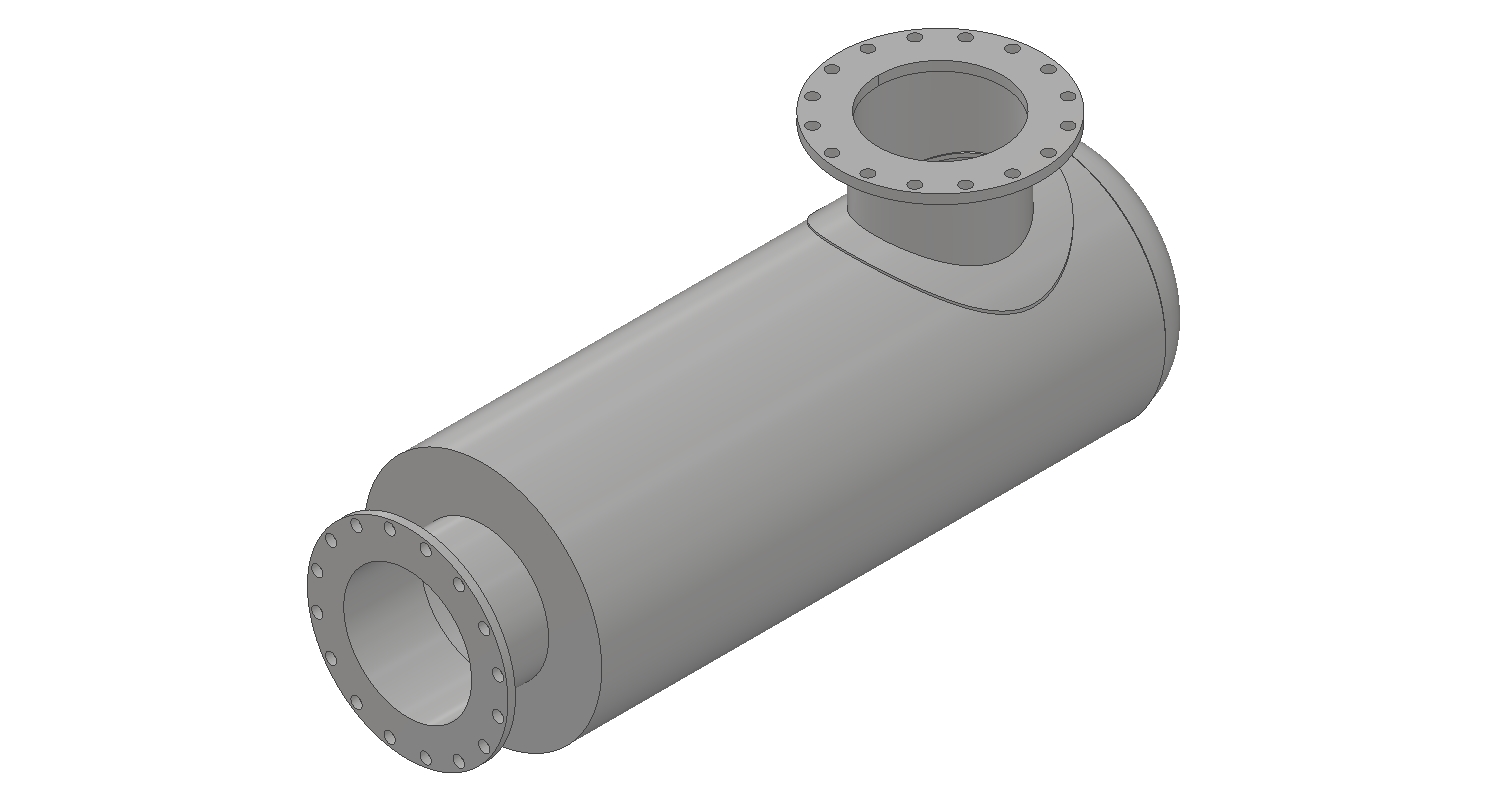

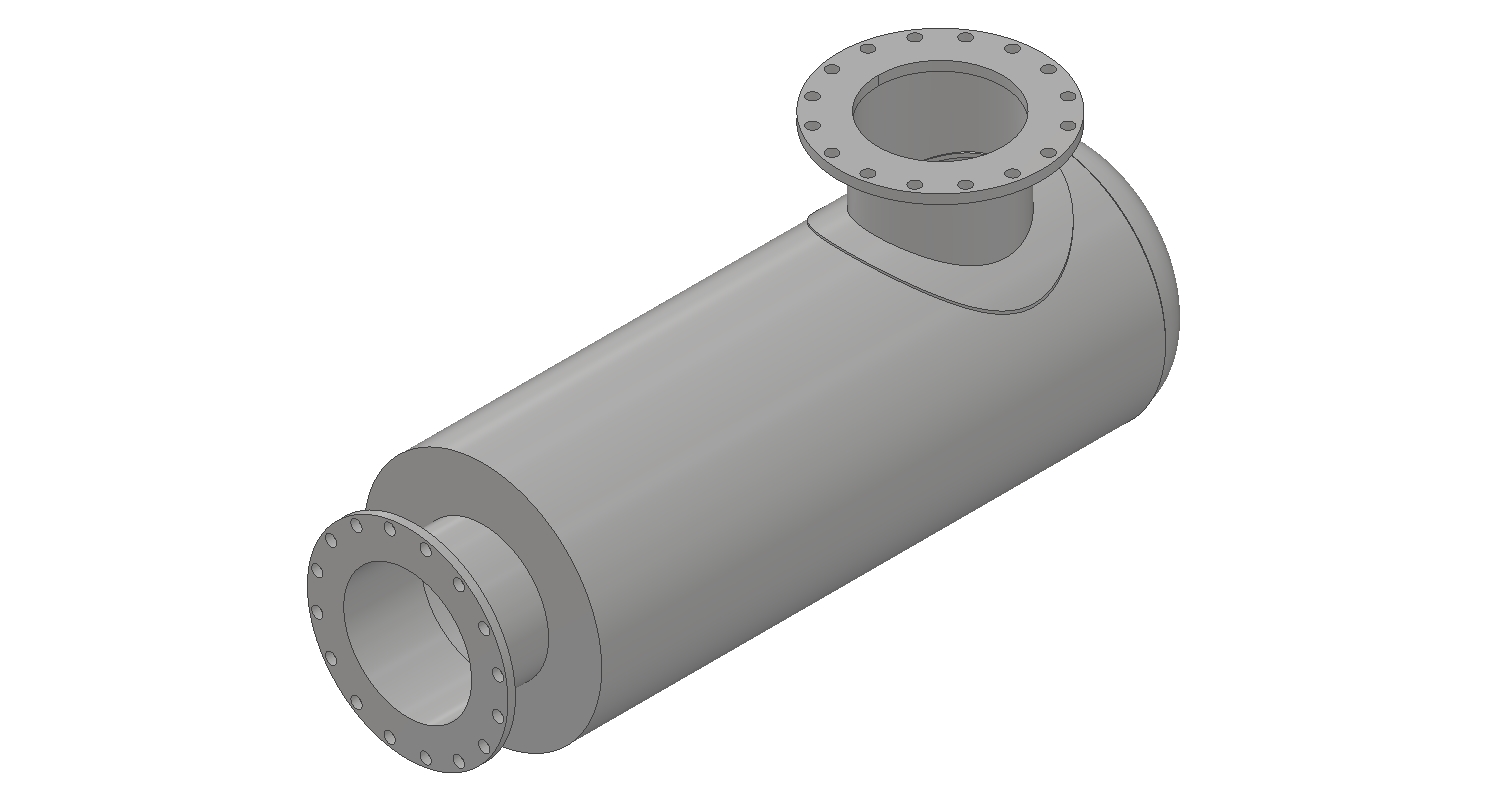

Circular Attenuators

- Available in various sizes and various widths

- Can be modular for heavy or awkward installations

- Made from a range of materials and specifications

- Standard construction

- Pre-galvanised steel outer body

- Perforated steel inner

- Acoustic infill with glass cloth wrapping

- Galvanised disc ends

- Optional construction

- Painted RSA flanges

- Hot dipped galvanised steel RSA flanges

- Stainless steel construction

- Powder coated steel outer construction

- Pod type for higher attenuation

- Acoustic material can be wrapped in a polyester based film for moisture laden environments

Reactive Silencers

Silencers designed for use on roots and other positive displacement blowers and compressors use reactive silencing technology to reduce the noise produced by the machine to a minimum. The advantage of this approach is that reactive designs do not use any form of sound absorption material giving the silencers a much longer life and removing any possibility of contamination of product or machinery downstream of the compressor. This allows effective silencers to be installed in food applications, pharmaceuticals, air handling systems, chemical plants and even water treatment where clogging of downstream diffusers is a problem with conventional silencers.

- Available in various sizes

- Can be inlet or discharge

- Filters can be separate or integral on inlet

Made from a range of materials and specifications

- Standard construction

- All silencers are manufactured from a minimum thickness of 5mm carbon steel internally and externally

- Optional construction

- Silencers can also be manufactured from stainless steels, aluminium or nickel based alloys such as Hasteloy for very corrosive applications

- Flanges can be British Standard, ANSI, DIN or to any customer preference

- For high pressure applications the external shells can be designed to conform to British Standards or ASME pressure vessel codes

Sizing information:

- Nature of machine, i.e., roots blower, reciprocating compressor, vane pump, etc.

- Flowrate

- Operating temperature

- Operating pressure

- Machine speed

- Number of lobes, vanes, cylinders per stage, etc.

- Nature of gas (air, steam, other - molecular weight & Cp/Cv value)

All products are bespoke and are designed to meet the specification required by the customer.

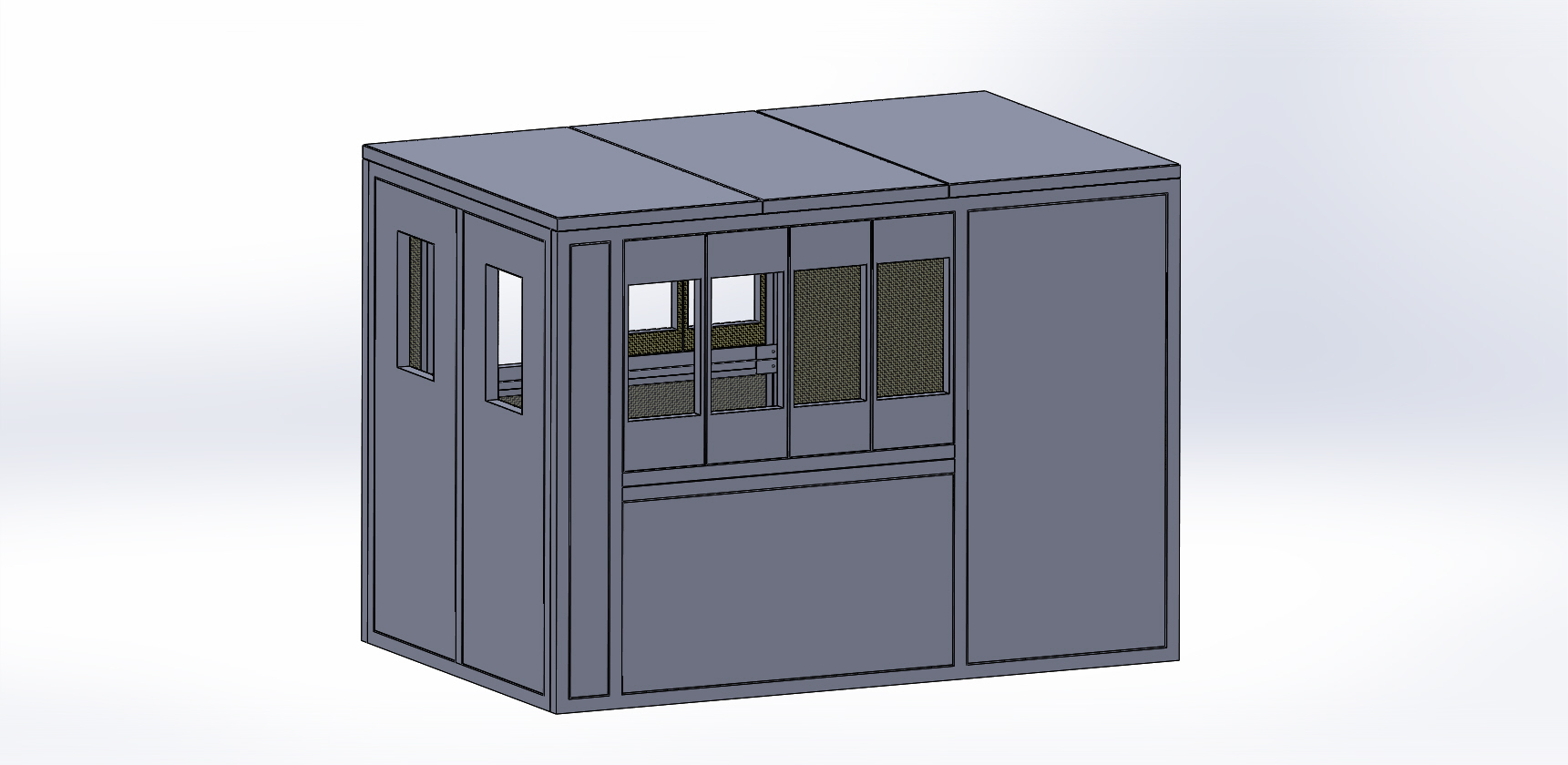

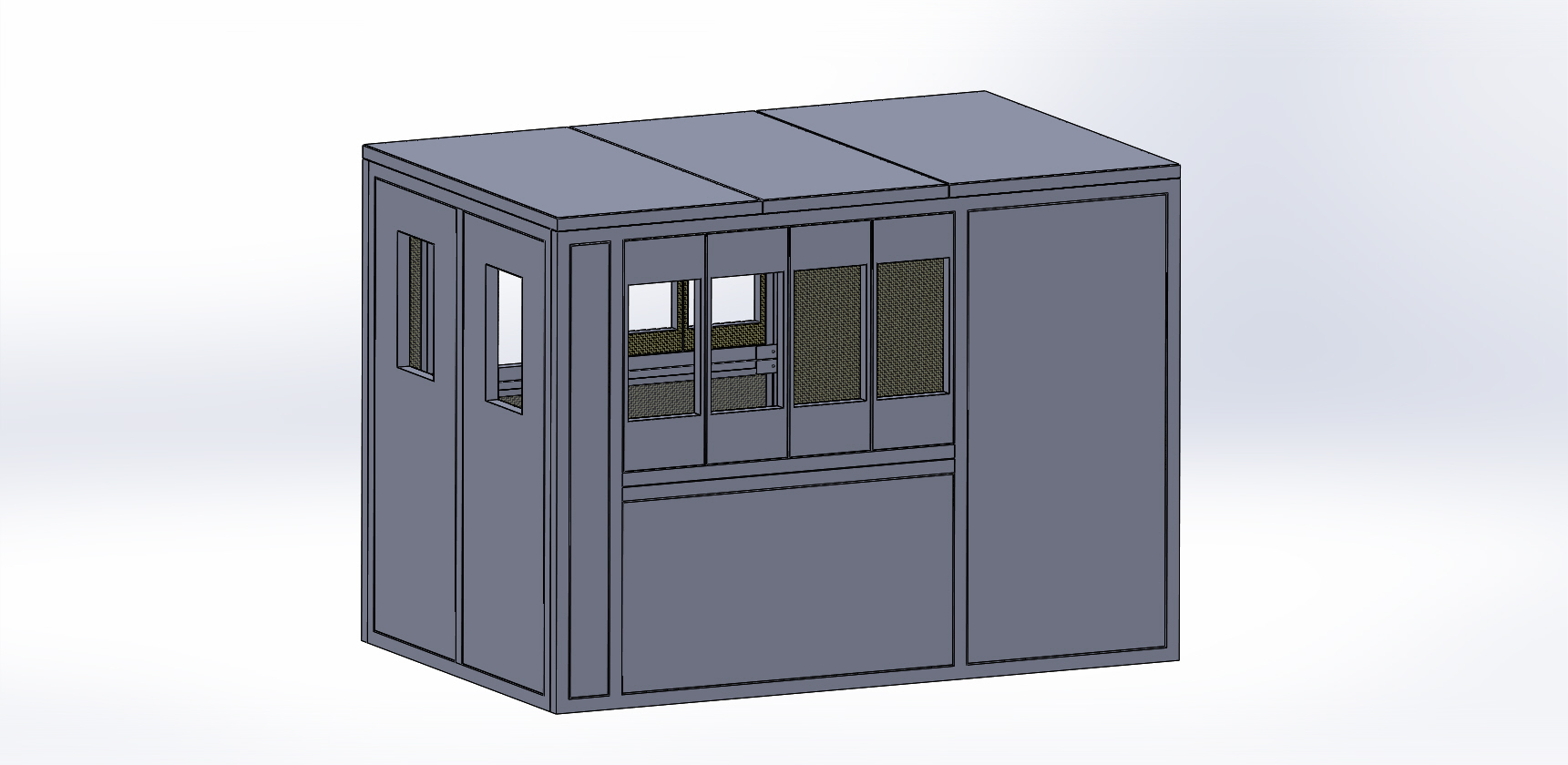

Acoustic Enclosures

- Can be designed as bolt together panels or frame type

- Hinged doors

- Glazed panels

- Natural or forced ventilation

- Made from a range of materials and specifications

- Standard construction

- Pre-galvanised steel outer body

- Perforated steel inner

- Acoustic infill with glass cloth wrapping

- Bolted panels

- Optional construction

- RSA frame or HS frame

- Stainless steel construction

- Powder coated steel outer construction

- FDA approved materials

- Acoustic material can be wrapped in a polyester based film for pharmaceutical or food environments

All products are bespoke and are designed to meet the specification required by the customer. The frequency spectrum is used to ensure a cost effective solution.

Beechfield Design Consultancy Limited can attend site and perform a no obligation noise survey and then offer a suitable bespoke solution.